Two Florida entrepreneurs find a home for InnovaKnits at the Manufacturing Solutions Center in Conover, NC

Blog Post from North Carolina Manufacturing Extension Partnership

InnovaKnits is a specialized contract manufacturer that provides flat knit consulting and develops domestic flat knit textile products for the medical, wearable electronics, and technical fields. Other industry applications include aerospace, energy, performance athletics, orthotics and prosthetics, molding and composites, hosiery and high-end fashion and apparel. In addition to product development services, InnovaKnits offers its customers inbound and outbound training and consulting services on STOLL knitting equipment.

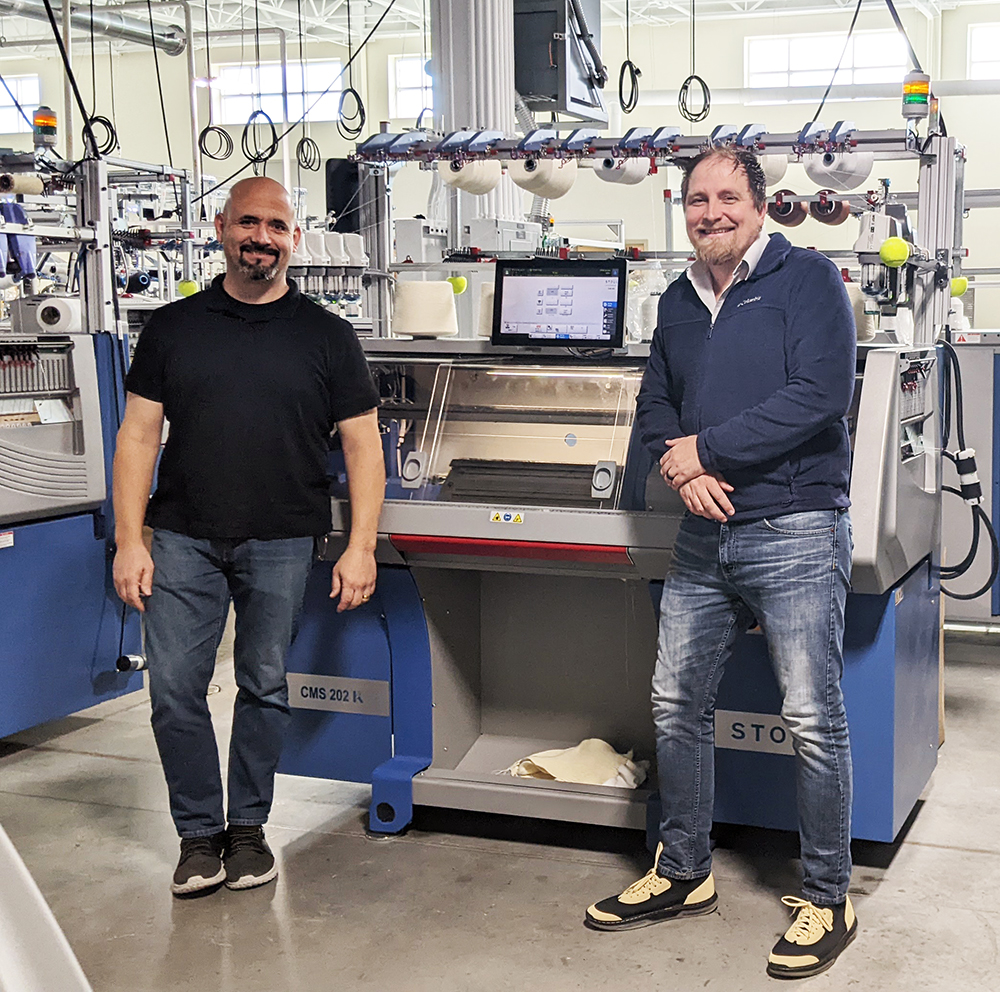

Partners Neil Tagner and Jason Wilkins moved their entrepreneurial operations from Florida to the Manufacturing Solutions Center business incubator in Conover, North Carolina, in 2015 and officially launched in 2016. The Manufacturing Solutions Center is part of Catawba Valley Community College. It works with traditional manufacturers and manufacturing start-ups in design, research, development, prototyping and product testing, and provides connections to industry experts and domestic resources.

By age 12, Tagner was programming flatbed knitting machines and working in his parents’ sweater manufacturing plant and high-end apparel knitting mills across the USA and abroad before NAFTA impacted the industry. Before launching InnovaKnits, Wilkins was employed at an injection molding business, manufacturing prosthetics for amputees. The two entrepreneurs took hosiery classes at the Manufacturing Solutions Center and worked on implementing machines to make compression hosiery for textiles adjacent to prosthetics products. Wilkins and Tagner realized that a much broader range of product solutions was possible with their combined specialized technical knowledge and the right equipment. And the concept of InnovaKnits was born.

Wilkins shared, “We knew it would be tough to efficiently build the type of manufacturing operation we initially visualized in Florida, and knew the textile supply chain was stronger in and around North Carolina. The Manufacturing Solutions Center is an entity that truly exists as a connect-the-dots in the textile world.”

InnovaKnits is focused on delivering technically superior products that require limited to no manual labor and post-knit assembly. Its technical expertise and mastery of specialized programmable equipment allow it to move bulk manufacturing production directly to automated knitting machines, eliminating costly domestic labor costs and enabling the company to compete more robustly with manufacturers worldwide with “Made in the U.S.A.” products.

In addition, compared to traditional cut and sew operations of a garment, where it starts with a roll of fabric, cuts of different pieces according to a pattern, and moves to different sewing operations to attach the pieces of the garment, InnovaKnits does not have any cut waste. Whatever yarn is going into the final textile is going into the machine. This lowers the concerns about environmental waste or hesitations to use expensive or technically advanced materials. The flatbed knitting process also helps eliminate or reduce labor compared to the labor involved in sewing production, where you often need many different people and operations to complete a product. Only one person is needed to run many knitting machines, and the product is often finished.

InnovaKnits does not produce fashion apparel or sweaters. Instead, it focuses on specialized, advanced technical, or medical uses. InnovaKnits performs 3D and multilayer knitting, complex intarsia patterning, weft and warp inlay of elastics, weft and warp inlay of conductive yarn or wire, plating and feeding of bare spandex, knitting with silicone yarns, knitting with high-strength UHMWPE yarns and has experience in the domestic production of knit uppers. InnovaKnits has developed unique solutions for various customers, including those in the automotive and aerospace industries and has grown with them.

The company’s uniqueness lies in its ability to create custom items that competitors cannot easily replicate. The business is focused on unique solutions for product development and technical applications. Wilkins said, “There are very few competitors in the USA because this skill set of people who know how to do this type of knitting and the knowledge to program this type of equipment basically, all moved overseas with the sweater industry in the nineties.”

The Manufacturing Solutions Center has been central to InnovaKnits’ business relationships and growth. In 2016, InnovaKnits became a resident in the business incubator space at the Manufacturing Solutions Center. The team at the Manufacturing Solutions Center continues to provide InnovaKnits with support, consulting and training on hosiery and knitting processes, equipment, supply chain, product development, and testing lab services. From an initial connection that the Manufacturing Solutions Center provided, InnovaKnits has grown that client relationship from a $30,000 income to a $500,000 per year account.

InnovaKnits now occupies 7,000 square feet of manufacturing space in the Manufacturing Solutions Building II. The Manufacturing Solutions Center II building is a public-private partnership between the City of Conover and the private equity group Whiskbroom. The Whiskbroom-owned portion of the building contains four operating companies that graduated from the Manufacturing Solutions Center I business incubator.

On the most recent survey in 2024 documenting Manufacturing Solutions Center technical support services and testing services provided to InnovaKnits, they reported a total economic impact of $515,000: $75,000 in increased sales, $300,000 in retained sales, $40,000 investment in new equipment, $100,000 in cost savings, one new job created and one retained job.

Comments

There are no comments yet.

Leave a Comment